-

welcome

High Quality Results

Shopwerks, Inc. is the area's leading business focused on industrial abrasive blasting, coatings and linings, and fireproofing. For almost two decades we have focused on controlling costs and meeting schedules while ensuring a quality product our customers can be proud of.

Mission Statement

The mission of Shopwerks, Inc. is to create lasting partnerships with our clients by providing a product that meets their expectations and to do so on schedule and in a safe work environment.

read moreour team

Pete Groves - President

Paul Rath - Project Manager

Mary Lopez - Inspection

Melinda Gimm - Shipping/Receiving

James Money - Accounts Payable/Receivable -

Our partners

Sherwin-Williams

Go to site|

msds & pds

Tnemec

Go to site|

msds & pds

Carboline

Go to site|

msds & pds

PPG Industries

Go to site|

msds & pdsour projects

interchange railing

for chicago ramps

interchange railing

for chicago ramps

packaging pipe

coated and stenciled

Pipe

In the coating process

World Trade Center

beam preservation

Trailer

Primed for coating

Galvanized pole

with portion coated

Decorative Railing

Blasted and Coated

Blasted pipe

Waiting to be coated

Various Pieces

for decorative railing

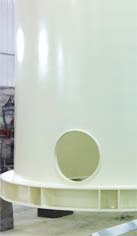

Coated Tanks

How to

find usShopwerks, Inc. Facilities

3014 South Broadway

Braceville, IL 60407 815.237.8000Telephone:

815.237.0825Fax:

E-mail: info@shopwerksinc.comShopwerks, Inc. Mailing

3014 South Broadway

Braceville, IL 60407

Click here to take our customer survey!FeedBack

About Shopwerk's Inc.

The History of Shoperwks

In 1994, Darren Sorensen and Dave Porth opened the doors of Shopwerks, Inc. At the time, the operation was in a small portion of the original Shopwerks shop. Several regular clients, along with many assorted customers, have utilized Shopwerks for their blasting and painting needs. Because of their quick growth, within five Shopwerks required more space and acquired the whole building they originally started in. This extra room was necessary to ensure the business grew and the quality of the work continued to improve.

In 2008, a 30,000 square foot facility was built on the Shopwerks property. This temperature-controlled building includes a full blasting outfit, a large painting room, a paint storage facility, and ample storage for customer material. It has also allowed Shopwerks to accept larger jobs and materials.

In 2024, Pete Groves purchased Shopwerks, Inc. from Darren Sorensen and became the new acting President.

Company Overview

In the past, Shopwerks, Inc has handled a wide range of jobs. Most common are structural metals, architectural metals, steel sheet/pipe piling, process piping, valves and tanks. However, we have also completed less-common jobs like bumpers, hand rail, and even structural steel recovered from the wreckage of the September 11 terrorist attacks. Our blasting technique includes daily contamination and cleanliness checks of our recycled steel grit, three-blast nozzle capabilities, and a continuous blast capability. We utilize the products of all major manufacturers of liquid applied coatings and linings. We also utilize mutiple sizes of Graco pumps to handle any sized job.

Privacy Policy

Any information we collect on our Site generally falls into the Personally Identifiable Information category. Personally Identifiable Information refers to information that lets us know specifically who you are. In general, you can visit our Site without telling us who you are or revealing any Personally Identifiable Information.

Except as disclosed in this Privacy Statement, we do not sell, trade, rent, or otherwise retransmit any Personally Identifiable Information we collect online unless we have your permission. Any Personally Identifiable Information you provide to us will be used for your purchases and retained in hard copy form of the original invoice as well as within our database system, which generates our invoices.

Links to third-party Web sites may be provided solely for your information and convenience, or to provide additional information for various other goods and services. If you use these links, you will leave our Site. This Privacy Statement does not cover the information practices of those Web sites linked to our Site, nor do we control their content or privacy policies. We suggest that you carefully review the privacy policies of each site you visit.

By using our Site, you acknowledge acceptance of this Privacy Statement in effect at the time of use. If you have any concerns about our use of your information or about this Privacy Statement, please send an e-mail to the address below. We will make every reasonable effort to address your concerns and remedy any problems you bring to our attention. This Privacy Statement was last revised on April 2012.

Our Affiliations

Shopwerks, Inc strives to adhear to industry standards

At Shopwerks, we are constantly working to better ourselves and our product. That is why we follow the standards of our industry's leading organizations. SSPC (the Society for Protective Coatings), and NACE both set standards that Shopwerks strive to meet. Although we have a full-time inspector on staff, we plan to have a full-time NACE-certified inspector in the near future.

Our Quality Assurance/Quality Control plan is also based off of standards set forth by these organizations. Furthermore, the Minnesota Department of Transportaion has certified our QA/QC program.

Abrasive Blast

Our Abrasive Blast technique ensures quality results for almost all materials

Shopwerks, Inc. takes pride in every aspect of our work. Our indoor work area allows us to control the temperature and weather conditions throughout our process. Our 60’ long x 20’ wide x 18’ high indoor Abrasive Blast Room offers ample space to allow a wide range of materials to be blasted to complete and order, or to prepare it for coating. We can also accomodate items longer than 60'. Offering various grades of blasting to suit the needs of our customers, our team pays close attention to every detail to ensure an uniform grade on materials being blasted.

Abrasive Blast

We use certified 100% recycled steel grit abrasive

Using recycled steel grit allows us to keep the cost to our customers at a minimum. Steel grit is the perfect medium to guarantee aggressive cleaning applications. Steel grit quickly strips many types of surface contaminants from steel and other metals. The nature of steel grit produces a surface that is optimal for superior adhesion of paint, epoxy, enamel, rubber and other coatings.

Each day prior to the beginning of blasting, the Shopwerks team conducts two tests to ensure our customers' material receives the utmost care. Both air cleanliness checks and steel grit contamination checks provide confirmation that our steel grit is clean and ready to be used.

Abrasive Blast

Our blasting equipment allows for a quick and detailed job every time

To ensure quick completion of even the biggest projects, our blast room has three-blast nozzle capabilities along with continuous blasting capabilities. .

Coatings and Linings

The perfect match for your coatings and linings needs!

Our team has years of experience in the industrial coatings and linings industry, ensuring your material gets the high-quality attention to detail it deserves. Our 180’ long by 84’ wide paint facility is large enough to accomodate any sized project and allows ample room to complete multiple jobs simultaneously. Our paint facility is also temperature controlled to provide a uniform consistent coating and lining curing process.

Coatings and Linings

Shopwerks, Inc. uses only the best products and equipment to ensure top-notch results

We apply liquid spray coatings and linings from all major coating manufacturers. The products we use include 100% Solids Polyurethane, Poly Urea, and Epoxies. We are able to order the coatings and linings you need from one of our many suppliers to meet your requiremnets. Oftentimes our customers choose to supply their own coatings and linings material for us to spray. Our paint is stored in out temperature-controlled, explosion proof paint storage room.

Coatings and Linings

The right equipment for any size job

. Shopwerks, Inc has coated everything from small hardware to large tanker trucks. We utilize multiple sizes of Graco Pumps for all coating and lining requirements and recently began using a new E-XP2 Reactor for Spray Applications of 100% Solids Polyurethanes and Epoxies.

Fireproofing

Shopwerks is now offering fireproofing services

Shopwerks, Inc. has recently become certified by Carboline to apply the Carboline line of Intumescent and Cementitious Fireproofing products. This means we can now offer solutions for jobs where steel is required to be protected from fire.

Fireproofing

Shopwerks is now offering fireproofing services

More details on our Fireproofing will be available in the very near future.

Fireproofing

Shopwerks is now offering fireproofing services

More details on our Fireproofing will be available in the very near future.

Abrasive Blast

We use certified 100% recycled steel grit abrasive

Our Team

Pete Groves, President - Email Pete Groves

Paul Rath, Project Manager - Email Paul Rath

Mary Lopez, Inspector - Email Mary Lopez

Melinda Gimm, Shipping & Receiving - Email Melinda Gimm

James Money, Accounts Payable/Receivable - Email James Money